Bringing Ideas to Life with Expert 3D Printing, Scanning & Prototyping Services in Fremantle.

At Brigmann Pty Ltd in Fremantle, we offer 3D printing, 3D scanning and machining services to individuals and businesses to bring their ideas to life.

- Over 20 years of experience in Fabrication, 3D printing and prototyping.

- Committed to delivering high-quality, cost-effective solutions that meet the needs of our clients.

We prefer using 3D printed models in our prototyping projects to review with the client before CNC machining the parts in metal.

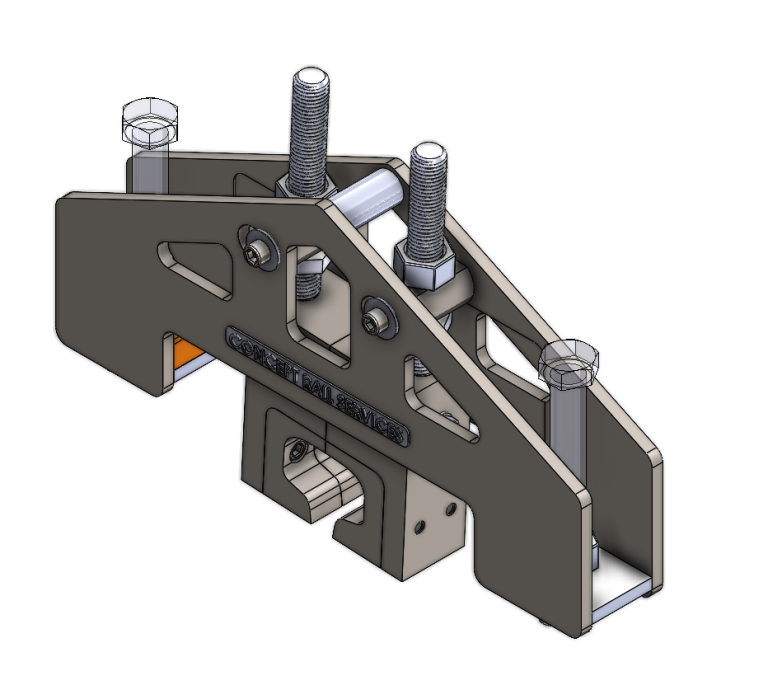

- Rail Road Track Installation Jig

Our client asked us to design and fabricate a tool which could be used to install floating rail road tracks. The criterium was that the angle of the track was adjustable to create the required angle ff the train track.

We used our FDM printers to produce models with which we presented to the client for their opinion.

The first one was in a scale which allowed us to print the parts easy and fast.

After the first approval round we printed the parts in 1:1 and used this model on site to verify the practicality of the design.

We manufactured later 20 tools for the installation of two rail road crossings. Please refer to the Prototyping page for more details

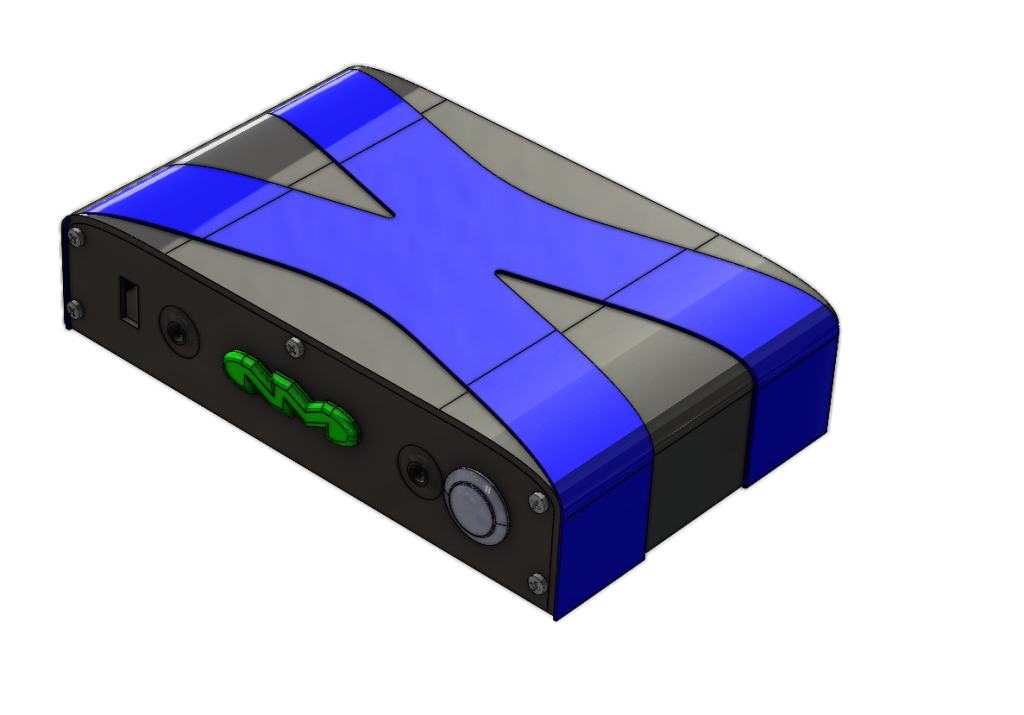

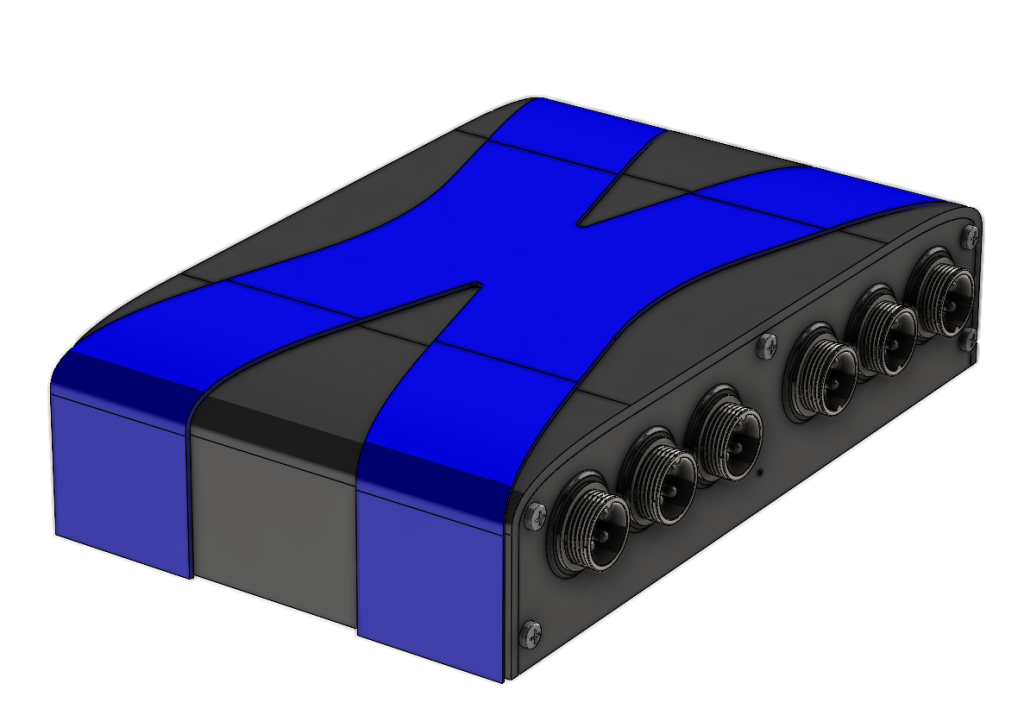

- Electronics and Data Logger Housing

As part of an electronics R&D project, we developed a custom-built data logger designed to interface with strain gauges.

Our team handled the complete process: designing, assembling, and thoroughly testing the electronic circuitry to ensure reliable performance in the field.

The finalized logger was installed on a C785 dump truck and monitored over several weeks under real-world operating conditions.

We collected key performance data, conducted detailed analysis, and derived actionable insights to support further refinement and system development.

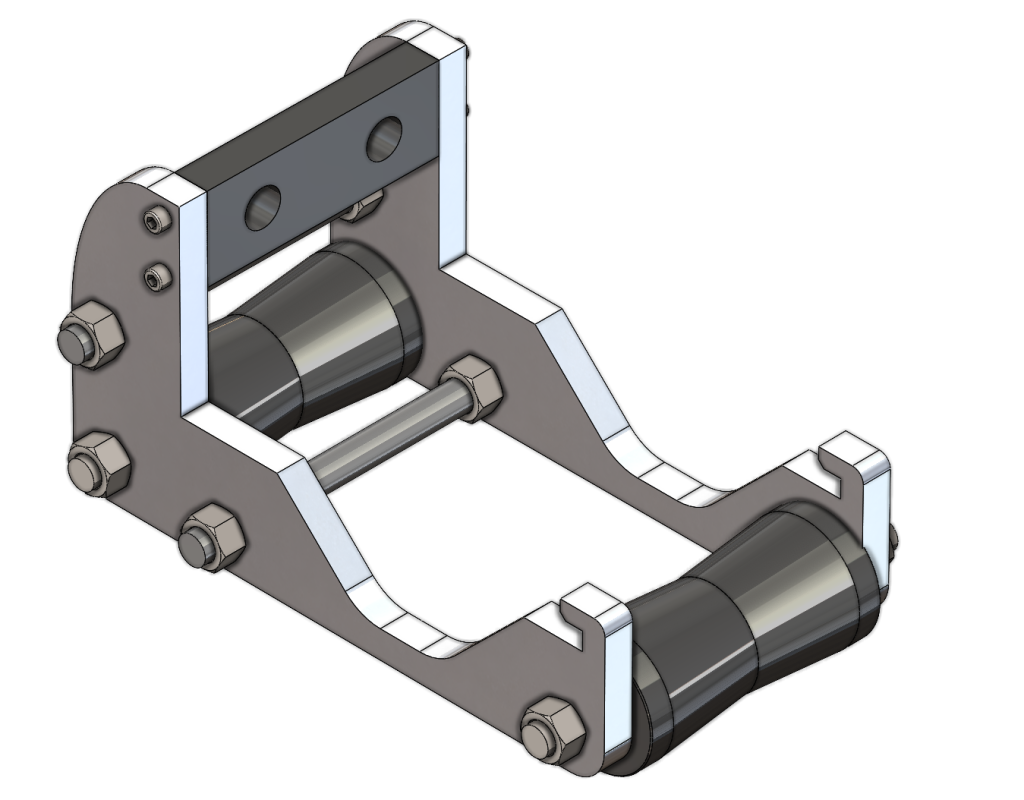

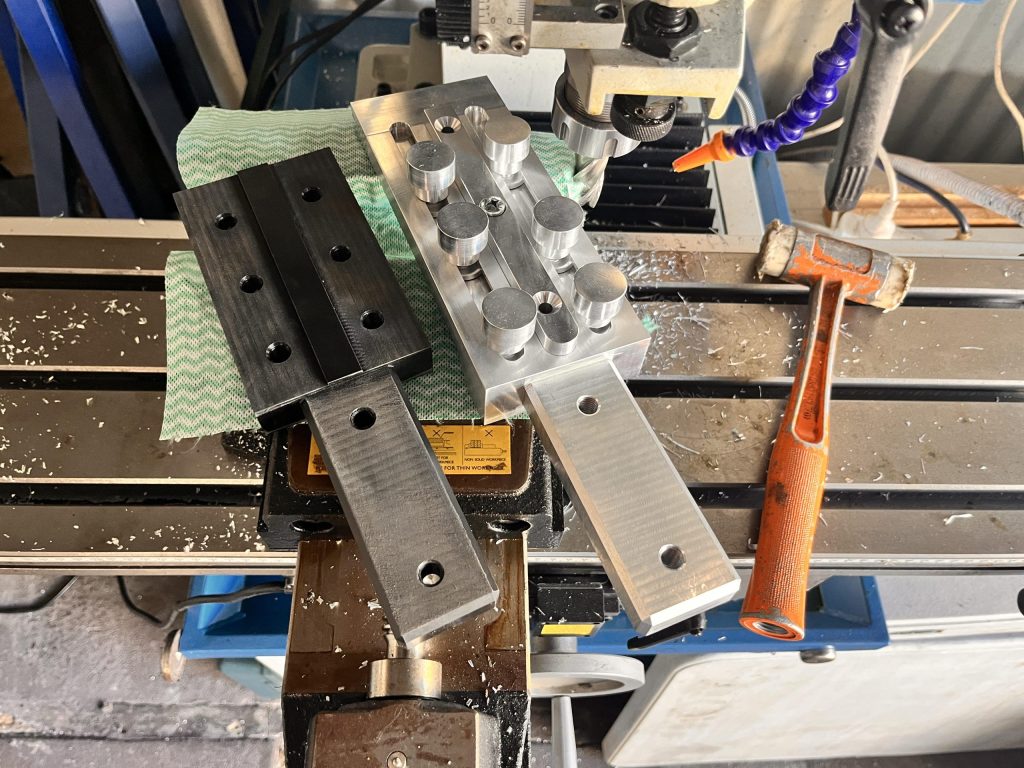

- Haul Truck Service Tool

Our Client approach us to help him to design a tool for one of their processes. We started with an initial interview in which we created hand sketches and general dimensions as well defined restrictions for the design.

We then created the first designs in CAD and discussed the geometry with our client.

We then printed the 1:1 model which we tested on site to ensure the dimensions are correct and no details are overlooked.

We then changed the design according to the new information and created another iteration which was tested again.

After ensuring that the design might work we fabricated the design out of metal and various plastics which in our workshop using turning and milling processes.

- Rail Gauge

- 3D Printed Dump Truck Tray

Our Client asked us to produce a scale model of their product, so it is possible for them to show it to clients and to explain the unique features this way.

The approach was to export the design from CAD and to import it into a post processing software in which we created the model for 3D Printing. This is important to ensure that the features are possible to be printed. Scaled models sometimes have tiny features which will not show in a 3D Print.

The model size was 500mm in length. Also created a enclosure for shipment and storage to ensure the model could be shipped around the world with out damage