Below is a selection of projects we’ve had the privilege to contribute to across a wide range of industries and sectors. Each one reflects our unwavering commitment to engineering excellence, practical innovation, and collaborative problem-solving.

In keeping with our respect for client confidentiality and the protection of intellectual property (IP) under non-disclosure agreements (NDAs), the details presented here are intentionally limited, and all imagery is generic. Nonetheless, each project tells a deeper story—of challenges overcome, value delivered, and quality assured.

We invite you to explore this portfolio as a representation of the breadth, depth, and reliability of Brigmann’s capabilities. Behind every summary lies the full measure of our expertise, dedication, and integrity.

Railroad Crossing Installation – Design, Tooling & Precision Placement

Brigmann was engaged by a client to support the design and installation of two rail crossings near Perth, with a focus on accuracy, durability, and ease of installation within tight construction schedules.

Key aspects of the project included:

Crossing Design:

Brigmann developed the custom design of the rail crossings, tailored to site-specific requirements and load conditions. The design ensured smooth vehicle transition over the tracks while accommodating structural and geometric constraints. Final certification of the design was carried out by an independent structural engineer, ensuring compliance with applicable rail and road standards.Specialised Installation Tooling:

To facilitate precise installation, Brigmann designed and manufactured custom installation tools that enabled exact alignment and positioning of the rails within the concrete formwork. These tools were critical to maintaining tolerances and ensuring long-term track stability.Precision Rail Placement & Resin Fixing:

Brigmann’s team managed the on-site placement and alignment of the rails, ensuring they were set to specification prior to fixing. Once correctly positioned, a high-performance resin system was used to secure the rails in place, providing a durable bond and resistance to thermal expansion, vibration, and operational loads.

Brigmann’s involvement ensured the successful, on-time delivery of both crossings with minimal disruption and high installation precision, contributing to a reliable and low-maintenance rail infrastructure solution.

Custom Modular Service Platform – Design & Compliance with AS 1657

Brigmann was engaged to design a custom modular service platform aimed at providing safe and efficient access for maintenance personnel. The project demanded strict adherence to AS 1657, the Australian Standard governing the design, construction, and installation of fixed platforms, walkways, stairways, and ladders.

Key project highlights include:

Full Regulatory Compliance:

The platform was engineered to meet all safety and dimensional requirements outlined in AS 1657, ensuring personnel safety and regulatory approval.Modular Design Approach:

The modular nature of the platform enabled flexible installation and future scalability, allowing easy adaptation to site-specific conditions and maintenance needs.Focus on Ergonomics and Accessibility:

The design prioritized user ergonomics, clear access routes, and maintenance efficiency without compromising structural integrity.

Brigmann’s solution delivered a safe, durable, and practical platform tailored to the client’s operational and safety requirements.

Compact CVT Gear for Pushbike – Design & Development

Brigmann assisted a client in the design and development of a compact continuously variable transmission (CVT) gear tailored specifically for use in a pushbike. This innovative gearing solution aimed to provide smooth, seamless speed variation and enhanced rider efficiency without the complexity and weight of traditional multi-gear systems.

Key project elements included:

Compact and Lightweight Design:

The CVT gear was engineered to fit within the limited space constraints of a bicycle drivetrain, prioritizing minimal weight and streamlined integration.Smooth Variable Transmission:

By enabling continuous gear ratio adjustment, the design improves rider comfort and performance over varying terrains and speeds.Collaborative Development:

Brigmann worked closely with the client throughout the design and prototyping phases to ensure the product met performance and durability targets.

Explore the project and see the CVT gear in action on YouTube:

Compact CVT Gear for Pushbike

Radiator Production Test Station – Design, Build & Automation

Brigmann was commissioned to design and build a custom test station to support the production and quality assurance of automotive radiators. The solution required a robust, modular structure and a fully automated control system to manage testing sequences and ensure repeatable, accurate results in a production environment.

Key aspects of the project included:

Structural Design with Aluminium Extrusions:

The test station’s frame was constructed using industrial-grade aluminium extrusions, chosen for their modularity, durability, and ease of assembly. This approach enabled quick integration of fixtures, safety enclosures, and sensor mounting points, while maintaining a clean and professional industrial aesthetic.Automation and Control with Siemens PLC:

Brigmann implemented a Siemens PLC to control the sequence of actuators, sensors, and test parameters. This included programming logic for pressure testing, fluid handling, timing cycles, and pass/fail evaluations. The user interface and control logic were developed to be both operator-friendly and suitable for integration into a larger production line.In-House Machining and Fabrication:

All custom mechanical components, including brackets, sensor mounts, and actuator fixtures, were machined in-house using Brigmann’s own lathe and CNC milling capabilities. This ensured full control over tolerances, quality, and delivery timelines.

The completed system provided a reliable, automated testing solution tailored to the client’s specific production requirements, enhancing quality control, operator efficiency, and manufacturing throughput.

Two-Story Passive House – Timber Structure Design & Modular Prefabrication

Brigmann was commissioned to design the timber structural system for a two-story passive house, aligning with both energy efficiency goals and modern construction standards. The project required an in-depth understanding of applicable residential timber design codes and passive house principles, with a strong emphasis on sustainability, precision, and buildability.

Key elements of the project included:

Standards-Based Structural Design:

Brigmann conducted a thorough review of relevant Australian timber construction standards to ensure structural compliance and durability. The design accounted for long-term performance, thermal bridging minimization, and integration with passive house building envelope requirements.Modular Prefabrication:

The house was designed as a prefabricated modular kit, with all structural wall and floor elements manufactured off-site in a controlled factory environment. This approach significantly reduced on-site construction time and improved build quality.On-Site Assembly Support:

Once fabricated, the prefabricated wall and floor panels were transported to the building site, where they were assembled by the builder according to Brigmann’s detailed construction drawings and specifications. Brigmann supported the process by ensuring dimensional accuracy, efficient sequencing, and structural alignment throughout the build.

This project showcases Brigmann’s ability to combine sustainable design practices with modern prefabrication methods, contributing to the delivery of a high-performance, energy-efficient residence.

Dump Truck Tray – Engineering Design and Analysis

Brigmann is collaborating with a well-established dump truck tray manufacturer to deliver the full engineering scope for a high-capacity dump truck tray rated for over 360 tonnes. This includes design, structural analysis, thermal optimization, and certification of the steel body in accordance with OEM requirements and industry standards.

Key elements of the project include:

Thermally-Optimized Design:

The tray features an integrated heating system that utilizes engine exhaust heat to warm the steel body. This design helps to prevent material carry-back by reducing material adhesion and freezing in cold conditions. Brigmann conducted Computational Fluid Dynamics (CFD) simulations to model the exhaust gas flow, optimize heat distribution, and verify the thermal performance of the system under various operating conditions.Discrete Element Method (DEM) Simulations:

To ensure optimal material flow and minimize wear, Brigmann performed detailed DEM studies. These simulations helped assess how the tray geometry affects load distribution, dumping performance, and internal wear patterns. Furthermore, DEM data was used to validate the tray’s design against OEM center-of-gravity (COG) requirements, ensuring safe and balanced operation.Finite Element Analysis (FEA) and Structural Certification:

For structural verification, Brigmann conducted comprehensive FEA simulations to analyze stress, deformation, and fatigue under dynamic loading conditions. These studies considered various loading scenarios, including haul cycles, impacts, and torsional loads, to simulate real-world conditions. Based on these results, Brigmann prepared detailed engineering documentation and certification reports to support manufacturing and compliance with OEM standards.

The result is a highly engineered, performance-optimized dump body designed to withstand extreme loading while improving material handling efficiency and reducing maintenance costs.

Maintainability Improvement for Bulk Material Equipment – Analysis, Design & Prototyping

A client in the heavy industry sector engaged Brigmann to improve the maintainability and reliability of their bulk material handling equipment, with the goal of reducing downtime, minimizing operational disruptions, and improving safety during maintenance activities.

The project was delivered in several key phases:

Performance Review & Failure Analysis:

Brigmann conducted comprehensive studies and reviews of the client’s existing equipment, focusing on historical performance data, maintenance logs, and failure reports. This analysis identified critical failure points, high-risk components, and areas with excessive maintenance time or complexity.Benefit-Cost Analysis & ROI Prioritization:

Using the findings from the initial review, Brigmann developed a Benefit-Cost Matrix to systematically evaluate potential improvement initiatives. Projects were then prioritized based on their expected return on investment (ROI), balancing impact with implementation effort.Tool and Platform Design:

Selected improvement initiatives included the design, certification, and prototyping of custom tools, access platforms, and handling equipment to streamline maintenance activities and improve worker safety. All designs adhered to relevant industry standards and were engineered to withstand the demanding conditions of bulk material operations.Prototyping & Validation:

Brigmann produced functional prototypes for on-site testing and validation, incorporating feedback from maintenance teams to ensure usability and real-world effectiveness.

This holistic approach enabled the client to systematically reduce maintenance complexity, improve equipment uptime, and enhance overall operational efficiency.

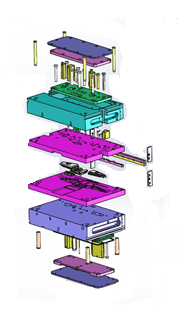

Hotmelt Injection Molding Tools – Design & Manufacturing for Electronics Encapsulation

Brigmann was entrusted with the conceptualization, design, and fabrication of specialized injection molding tools for use in Hotmelt plastic injection applications. This project focused on the protection of sensitive electronic components and connectors, which are often exposed to harsh environmental conditions.

Key aspects of the project included:

Application-Specific Tool Design:

The tools were engineered specifically for Hotmelt encapsulation, a process that demands precise control over flow characteristics, temperature, and cavity design to ensure full and reliable coverage of delicate components without damage.Electronics Protection & Environmental Sealing:

The primary objective was to develop a solution that effectively seals and protects electronic assemblies and connectors from moisture, dust, vibration, and mechanical stress. The resulting Hotmelt overmolding process ensures long-term durability and performance, especially in automotive, industrial, and outdoor applications.Complete In-House Development:

Brigmann managed the entire development process in-house, from initial design and simulation through to tool machining and final testing. This allowed for full control over tolerances, material selection, and quality assurance.

The success of this project underscores Brigmann’s capability to deliver precision tooling solutions for advanced manufacturing processes, particularly where reliability and environmental protection are mission-critical.

Injection Molding Machines – Base Unit and Machine Design

Brigmann was commissioned to finalize the design of a series of injection molding machines, with a particular focus on developing a robust and modular base unit. This base served as the critical foundation for the machines, requiring careful consideration of structural strength, manufacturability, and integration.

Key project highlights include:

Aluminium Extrusion Base Unit:

Brigmann engineered a durable base frame constructed from industrial-grade aluminium extrusions, chosen for their excellent strength-to-weight ratio, modularity, and ease of assembly. The design balanced rigidity and flexibility, enabling efficient manufacturing and adaptability to different machine configurations.Comprehensive Machine Design:

Beyond the base unit, Brigmann took responsibility for the complete machine design, ensuring all components and systems were optimized for seamless integration with the base structure. This holistic approach focused on practical functionality, serviceability, and operational efficiency.Design for Manufacturing & Assembly (DFMA):

The project emphasized DFMA principles to reduce complexity, minimize production costs, and accelerate time to market without compromising quality or performance.

This project demonstrates Brigmann’s expertise in delivering integrated mechanical designs that merge structural integrity with operational excellence in industrial machinery.