At Brigmann, we create integrated automation and robotics solutions that combine the strengths of robots, cobots, and manual workstations into a streamlined and efficient value stream. Our focus is not just on automation, but on smart, process-driven design that delivers real-world performance.

We work with renowned manufacturers such as ABB, KUKA and UR Robotics to ensure the best-fit robotic hardware for your application. Beyond the robots themselves, we leverage our extensive network of high-quality peripheral components—including aluminium extrusion systems from item24, tool changers, and safety equipment—to deliver complete workstation solutions.

For End-of-Arm Tooling (EOAT), we offer both custom-designed tools tailored to your process and a wide selection of off-the-shelf options to suit your budget and timeline. From concept to commissioning, we deliver automation solutions that are robust, scalable, and ready for the future.

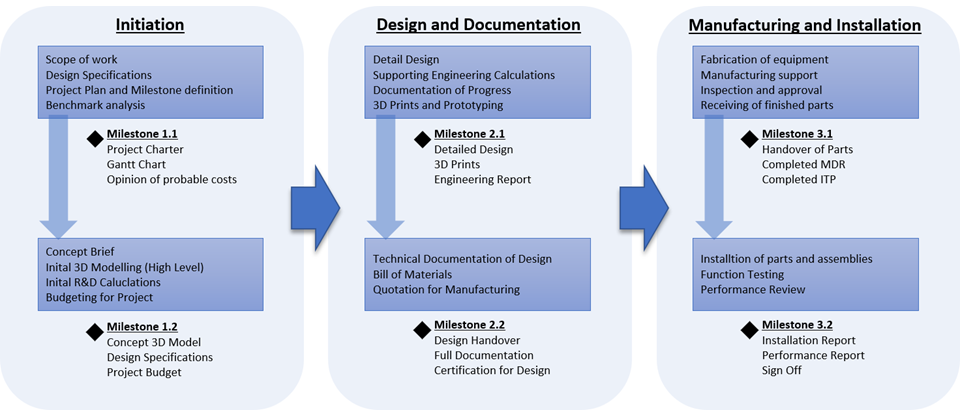

To align every detail with your goals, we follow a proven three-stage design process—from analysis and concept development to detailed design and implementation—ensuring the final solution matches your vision and operational requirements.

Workstation Design

At Brigmann, we believe that successful workstation design starts with a deep understanding of your current process. In the first stage, we analyze manual workflows using proven methods such as MTM (Methods-Time Measurement) to identify inefficiencies and improvement opportunities.

Rather than implementing drastic changes upfront, we focus on small, strategic adjustments that optimize the existing setup and lay the foundation for future integration of cobots and automation.

Using modular, high-quality components from item24 or Bosch Rexroth, we then develop scalable and ergonomic workstation solutions that evolve with your production needs—whether fully manual today or semi-automated tomorrow.

https://www.item24.com/en-au

https://www.boschrexroth.com/en/au/products/industrial-solutions/assembly-technology/aluminum-profile-kit/

Why Aluminium Extrusion Systems Matter

When designing custom workstations, flexibility and adaptability are key—especially in dynamic production environments. While the initial cost of aluminium extrusion systems like item24 or Bosch Rexroth may be higher per metre compared to traditional steel profiles, the long-term benefits far outweigh the difference.

Conventional methods, such as using RHS 40x40x2.0 or 35x35x2.0, often lock the design in place. Changes require welding, grinding, and repainting—adding time, cost, and the need for skilled labor and dedicated welding stations.

In contrast, aluminium extrusion systems allow for quick, clean, and precise adjustments using only basic tools like Allen keys. This makes it easy to test different layouts, integrate new components, or adapt the workstation for cobots and automation—without reworking the entire frame.

For projects where iteration and improvement are part of the process, aluminium extrusion provides unmatched efficiency, modularity, and scalability.